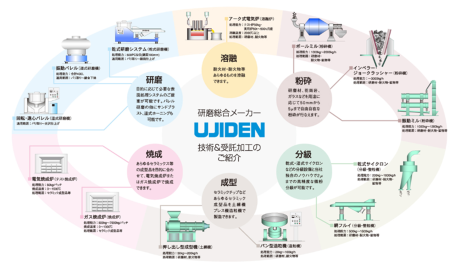

- Top

- Technical Information

- Manufacturing Technology

Manufacturing Technology

Our abrasive materials, which have earned the trust of many companies, are the result of many years of manufacturing technology. Even if the times change and the demands of the world change, we would like to meet the needs of our customers through these technologies.

We continue to hone our technology in order to earn the trust of our customers.

Melting

In the melting furnace, the raw materials are fused together (melted) to produce the desired product. It is important to use power as a heat source and strictly control the temperature.

Raw material melted at high temperature become ingot-like (lump-like) after cooling. We are

Crushing

The process of crushing ores, rocks, and molten-cooled ingot-shaped solids to a desired size is called "crushing".

In the crushing operation, "Crushing of agglomerated particles", "mixing and dispersion of several kinds of powders", "surface modification and activation of particles" and "increasing the specific surface area of particles" are performed.

Even for the same material, the characteristics may differ greatly depending on the grain size (fineness), and it may affect the subsequent processes.

Ujiden Chemicals fully understands the condition of the material to be crushed and the quality required for the product, and can freely grind all solids such as abrasives, granite, glass, etc. from 50 mm to 5 μm depending on the application.

Classification

Powders that have been crushed using gravity (difference in particle drop velocity and drop position), inertial force (using inertial force in fluid), centrifugal force (using fluid swirling), etc. are classified according to the particle size, density, shape, etc.

High-accuracy fine powder classification up to 2 μm is possible with classification equipment such as dry and wet cyclones and Ujiden’s original know-how.

Mixing / kneading-molding

Depending on the characteristics of the raw materials, they can be mixed and kneaded by the most suitable method, and molded by a kneading machine, pressing machine and granulating machine.

We mold ceramic molded products such as ceramic chips.

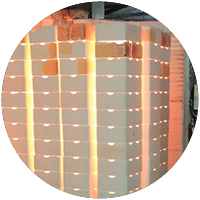

Firing (high-fired / sintering)

At the end of the manufacturing process, firing with high temperature heating ensures the strength of the molded product and determines the properties of the substance. After identifying the difference in product type, purpose of use, composition, etc., it is fired in an electric firing furnace or a gas firing furnace.

In the melting furnace, the raw materials are fused together (melted) to produce the desired product. It is important to use power as a heat source and strictly control the temperature.

Raw material melted at high temperature become ingot-like (lump-like) after cooling. We are capable of small-lot production, taking advantage of the versatility of an AC arc furnace that can handle all types of melting.

In regards to arc furnaces, heat treatment furnaces, and ceramic furnaces, we support our customers' "melting" needs with technologies accumulated over many years of operation.

Powders that have been crushed using gravity (difference in particle drop velocity and drop position), inertial force (using inertial force in fluid), centrifugal force (using fluid swirling), etc. are classified according to the particle size, density, shape, etc.

High-accuracy fine powder classification up to 2 μm is possible with classification

The process of crushing ores, rocks, and molten-cooled ingot-shaped solids to a desired size is called "crushing".

In the crushing operation, "Crushing of agglomerated particles", "mixing and dispersion of several kinds of powders", "surface modification and activation of particles" and "increasing the specific surface area of particles" are performed.

Even for the same material, the characteristics may differ greatly depending on the grain size (fineness), and it may affect the subsequent processes.

UJIDEN Chemicals fully understands the condition of the material to be crushed and the quality required for the product, and can freely grind all solids such as abrasives, granite, glass, etc. from 50 mm to 5 μm depending on the application.

equipment such as dry and wet cyclones and UJIDEN's original know-how.

Depending on the characteristics of the raw materials, they can be mixed and kneaded by the most suitable method, and molded by a kneading machine, pressing machine and granulating machine.

We mold ceramic molded products such as ceramic chips.

At the end of the manufacturing process, firing with high temperature heating ensures the strength of the molded product and determines the properties of the substance. After identifying the difference in product type, purpose of use, composition, etc., it is fired in an electric firing furnace or a gas firing furnace.

“UJIDEN's Business Survival” was launched in 2019, and it was built by superimposing current issues and environmental factors on the vision of UJIDEN's aim of being a 100-year manufacturing company.

The project’s name is the "DASH100 project".

We will classify our own products into three categories, plan new strategies, review manufacturing processes and costs, and plan to incorporate them into the company's medium- to long-term plan. The UJIDEN brand bears the name "Tosa" at the head of the main product. We believe that UJIDEN's mission is to send products that were born and raised in Kochi to the world and contribute to customers, business partners, as well as contribute to the local community and Kochi as a whole.

Sharing the vision with technology ‘mandala’

Looking back over the 80 years from the foundation of the company, it was never smooth sailing.Like many companies, there were times when we could feel a sense of crisis as economic waves and major disasters shook Japan.

However, many new challenges arose, and it was the fact that all of us shared in that sense of crisis that led us to be able to move forward together.

Even in situations where it was assumed to be “too difficult”, “have no time”, or “can't do anything”, the fact that we all responded positively by saying, “Let's devise something” or "If we can't do it, let's work with what we can do" gave us the power to shape our future.

In other words, "all are salespeople who represent and carry the company called UJIDEN on their backs". We are aiming for a further leap forward by polishing the "technology" that is the main business for a manufacturing company, by utilizing the "power" of the engine, that being all the people who work here.

The "Technical Mandala" serves as a guide. This is a strategic tool that shares a process and a vision to "understand the strengths and characteristics of our own technology and think about the direction of innovation that we should aim for."

With the introduction of the technical mandala, a system has been established in which each department and each person can re-recognize the organic connections in their work and carry out what they should do while utilizing PDCA on site.